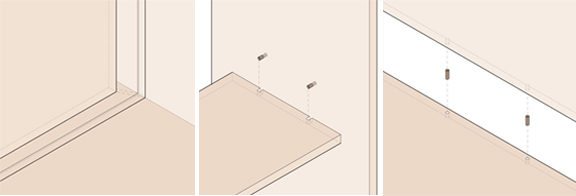

Part of our research examines the relationship between architectural conventions and their engagement with the body. The logic of industrial production permeates these conventions. As industrial production pushes for simplification, optimization, and an adherence to ‘machine’ protocols, the body demands accommodation, customization, and a figural adherence. The design of furniture consequently compromises the body more often than succumbing to costly craft. This furniture-scale intervention proposes a mediated balance between industrial production and its connection to the body. We follow an industrial-style logic for massing and detail assembly while leveraging the organic cabinetry details as an opportunity to better fit the hand and to aestheticize the plywood’s method of construction.

The object consists entirely of marine-grade Baltic birch plywood. We coated each piece with water-soluble polyurethane preserve its light color.

Wooden pegs and grooves connect the pieces to each other, allowing disassembly. While we milled pin holes on the faces of each piece, pin holes on the endgrains had to be hand-drilled with a custom jig.

CNC-milled cabinetry details aestheticize the plywood’s method of construction.

Prototypes test handle ergonomics.

We assembled groups of pieces in the lab and finished assembly on site.

Comments Off on Between Industrial Production and Ergonomics