Catenary Compression was developed as a research project, pairing up unlikely structural properties to work together for extraordinary circumstances. Working with light block construction that conventionally operates in compression; we set out to build a structural catenary that relieves the ground from any physical contact. A prototype was developed for the BSA-sponsored exhibit “Bigger than a Breadbox, Smaller than a Building” as both a provocation and experiment.

The aggregation is comprised of sixty individual carved and interlocking blocks that are CNC routed from polyurethane foam board to achieve the minimally required tolerances for tensile continuity. Numerous computer models analyzed the anticipated forces, and mockups were tested for loading and integrity. Ultimately the puzzle-like pieces were conjoined by inverted ‘keystones’, working against gravity to deflect the tensile forces.

Contrary to a dome construction, where the keystone serves as a crowning moment, here, a field of keystones connects the entire surface, each interlocked into its neighbors and all working in tandem to produce a single monolithic tensile surface. In turn, the terminus of the catenary, its nadir, is characterized by an ocular void acting as a tensile ring. The underbelly of the vault displays the continuity of the tensile surface, while the top surface remains articulated, as its carvings help to offset the necessary tolerances needed to overcome misalignments between blocks, a rustication of sorts.

The installation will be on view at the BSA Space through September.

Comments Off on Catenary Compression: the Tensile Vault, reconsidered

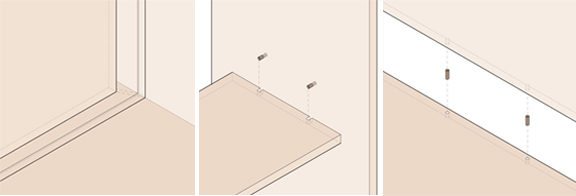

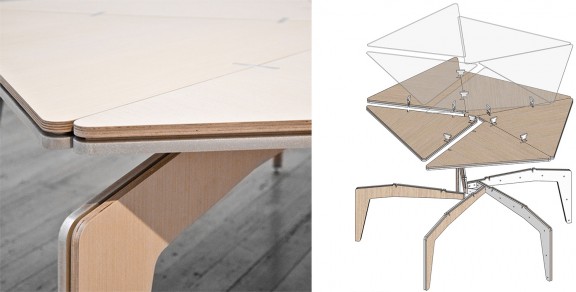

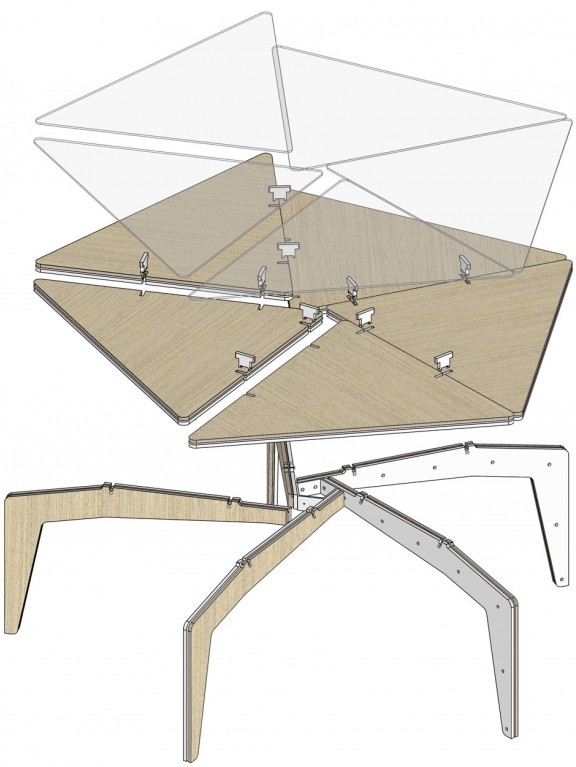

Exploded Axonometric drawing showing the assembly logic of the table.

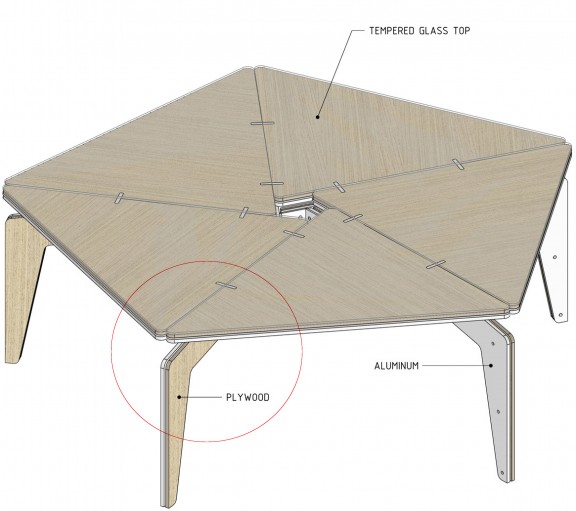

Exploded Axonometric drawing showing the assembly logic of the table. A mock-up was built to evaluate the material choices and test the custom fasteners.

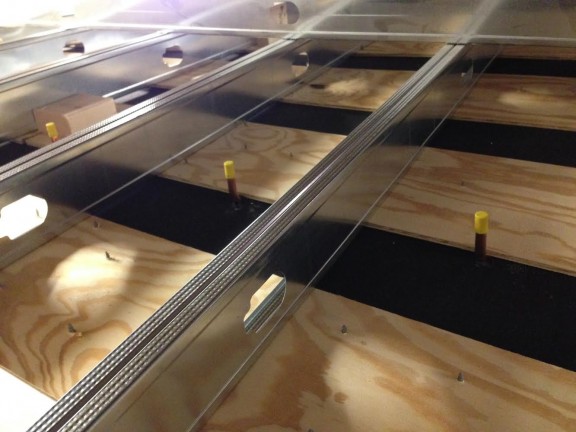

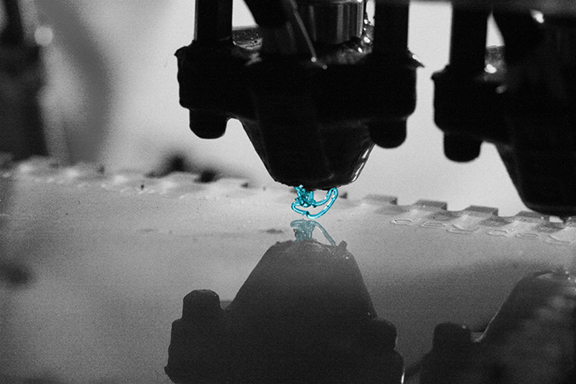

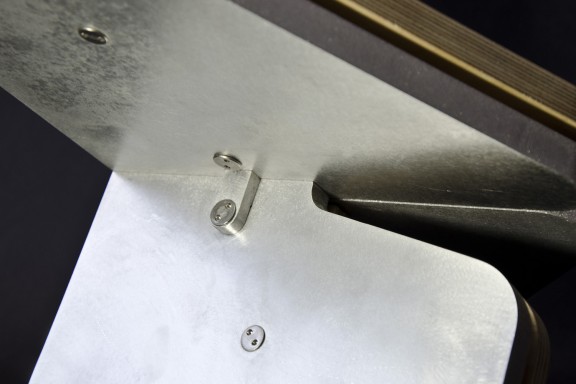

A mock-up was built to evaluate the material choices and test the custom fasteners. Waterjet-cut 6061 Aluminum features a non-directional satin finish. CNC-cut Plywood with an Apple-ply core is faced with White Anigre.

Waterjet-cut 6061 Aluminum features a non-directional satin finish. CNC-cut Plywood with an Apple-ply core is faced with White Anigre. The wood and aluminum are laminated together with Marine Epoxy.

The wood and aluminum are laminated together with Marine Epoxy. Tight tolerances are critical for the precision attachments.

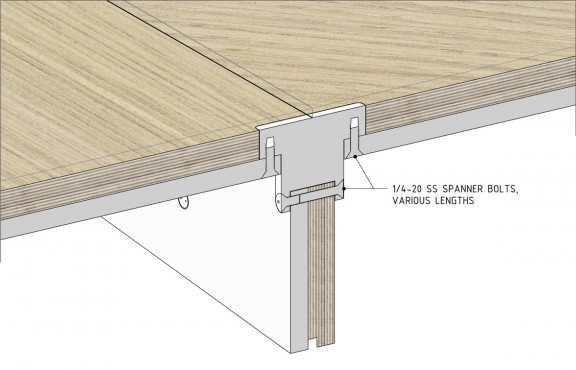

Tight tolerances are critical for the precision attachments. Detail Axonometric Section through the Leg / Table-top connection.

Detail Axonometric Section through the Leg / Table-top connection. The unique aluminum fasteners are machined by hand in our shop.

The unique aluminum fasteners are machined by hand in our shop.