Comments Off on Columns up at the new Kendall/MIT station!

Comments Off on Columns up at the new Kendall/MIT station!

Archetypes features a recent series by Canadian artist David K. Ross, who works at the interface of photography, film, and installation. His images of architectural mock-ups, staged at night with dramatic lighting that isolates structures from their surroundings, demonstrate how these objects have become a charged form of proto-architecture. The book offers an effective platform to consider what it means to pre-construct fragments of buildings in all their complexity. Published alongside Ross’s images are four essays framing the historical, technological, and civic significance of the mock-up.

For more information or to order a copy please click HERE.

Many of Ross’s works will be exhibited at upcoming shows in Zurich, Munich, Basel, and at Daniels Building’s Architecture and Design Gallery.

Comments Off on MIT mock-ups featured in David K. Ross’s new book

On July 10th the Adams Street Branch Library in Dorchester officially broke ground! Mayor Martin J. Walsh, along with the City’s Chief of Operations Patrick Brophy, Boston Public Library president David Leonard, and members of the community, including the Friends of the Adams Street Branch Library, gathered to celebrate the start of construction.

Mayor Walsh spoke to the undiminished importance of libraries in serving all members of the community and called the planned renovation “truly a library of the twenty-first century.”

NADAAA’s proposal for the Adams Street Branch Library renovation.

Boston Public Library President David Leonard commemorates the occasion.

Key team members, from left to right: Mayor Martin J. Walsh, BPL Major Projects Coordinator Lissa Schwab, NADAAA Project Architect Amin Tadj, BPL Major Projects Program Manager Alison Ford, PFD Project Manager Jim McGaffigan, NADAAA Project Manager Michael Schanbacher, PFD Assistant Director Tom Leahy, PFD Assistant Director for Design Paul Donnelly, and Mayor’s Office Chief of Operations Pat Brophy.

Pint-sized library-goers take part in the ground-breaking.

Read more about the renovation and Mayor Walsh’s plan to improve the Boston branch libraries HERE.

Comments Off on ADAMS STREET BRANCH LIBRARY BREAKS GROUND

The Adams Branch Library officially breaks ground on Wednesday, July 10th! NADAAA, alongside Mayor Martin J. Walsh, the Boston Public Library, and the Boston Public Facilities Department are excited to celebrate the start of construction on the new library in Dorchester.

Join us at 690 Adams Street in Dorchester at 5:30 pm for the ceremony, followed by a community celebration featuring the Choco-leles, who will lead a ukulele sing-along. Learn more about the the project development HERE.

Comments Off on JOIN US FOR THE ADAMS BRANCH GROUND-BREAKING

The brick facade on the RISD residence hall is officially complete! Next up, the shingled facade — the installation of these lightweight cement fiber panels is 20% complete. The building is due to open to students by the end of August.

Comments Off on BRICK FACADE COMPLETED AT RISD

As of April 2nd, 2019 the MIT Site 4 project was officially the tallest building in Cambridge! Right now the building is at 299′, but will reach 330′ by the end of

Comments Off on Tallest building in Cambridge (for now!)

September 2018 through March 2018

Comments Off on RISD construction timelapse

Image above from Odeh Engineers

NADAAA’s new residence hall project for the Rhode Island School of Design is going up at 60 Waterman. The team celebrated the ‘topping out’ on January 23rd. Neighbors, friends and the RISD community were invited to sign the final beam before it was hoisted to the 6th floor. In keeping with tradition, a small tree was placed on the beam. The tree, a gesture to the Scandinavian forest spirits, will remain atop the structure until the building is enclosed. After a string of freezing cold days, the building was resplendent during the ceremony, its golden cross-laminated timber (CLT) deck glowing in a steel frame. More than one person commented that it was a shame that the building could not remain that way.

Most architects are acutely aware of the paradox that in trying to build our best civilization we are among the planet’s greatest producers of waste. Construction garbage accounts for a disturbing percentage of the world’s refuse. Hence the excitement around the potential of CLT construction. Made of plies of kiln-dried soft-woods, CLT is poised to make a significant impact to the market in the near term. It can be cut to size in a factory, shipped, and installed without modification. The biggest financial challenge to using CLT tends to be logistics (e.g. how far is the job from the production facility), and with new plants coming online every few months, that may cease to be a problem.

60 Waterman was designed to take advantage of CLT’s dimensional stability and a maximum truck bed size. Five-ply planks were driven from Canada, 8 feet wide and 50 feet long. Due to the relatively light weight, the manufacturer fit many planks on a truck, so there was minimal strain in getting material to the erection crew. Weighing much less than precast concrete planks, CLT is capable of greater coverage, going up faster using a smaller crane and less fussiness than precast concrete plank. The building structure was complete in less than three weeks. CLT has no camber – it is joined to adjacent planks with a spline. If the CLT needs to be modified, it can quickly be cut with a chain saw. Try that with concrete.

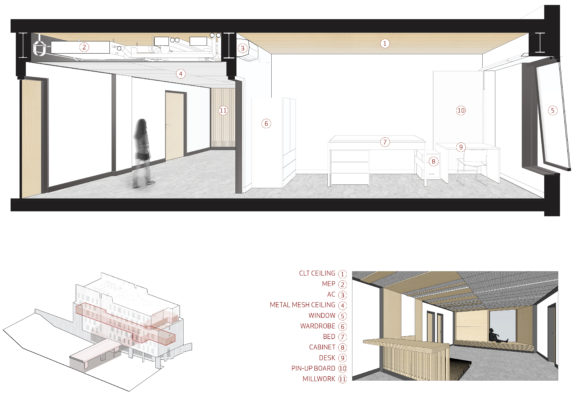

Using an Integrated Project Delivery, NADAAA worked with Shawmut Construction and subcontractors to coordinate a central utility spine in the corridors. Mechanical feeds and sidewall sprinklers afford maximum ceiling height and flexibility of layout for the bedrooms. Perhaps the most exciting thing about 60 Waterman’s design is the warmth that wood ceilings will bring to the building interior. That simple gesture is the byproduct of a design process driven to optimize construction time, budget control, and minimize material waste.

Along with the construction partners, NADAAA collaborated closely with structural engineer Odeh Engineers, Inc. to evaluate numerous options for the superstructure. The team ultimately chose the hybrid CLT system due to its inherent sustainability, beauty, and speed of construction. When this building opens in late August, it will be the first hybrid steel-CLT residence hall in New England, although likely not the last.

Comments Off on New England’s First Hybrid CLT-Steel Res Hall Structure

Foundations in and steel going up on the new residence hall!

Photo by Odeh Engineers

Comments Off on RISD RIGHT NOW

On October 5th RISD’s new Residence Hall officially broke ground! We are excited to announce we have been working with RISD to design this new addition to the Freshman Quad after having completed the Master Plan for the Quad early last year. More information can be found on RISD’s Campus Master Plan website HERE and more to come soon!

Comments Off on 60 Waterman Ground-Breaking